Why become a VERSO distributor ?

Most customers are small to mid-sized businesses in the signage, POS and large-format printing industries. The VSR’s exceptional versatility, even without a conveyor belt, allows them to cover virtually all cutting needs with a single machine-reducing investment, staffing requirements and floor space.

Larger companies in the same sector typically choose the VSR to increase capacity, improve reliability and streamline production, while expanding their range of services. In most cases, they already operate a flatbed cutting table (e.g., Zünd or Kongsberg) and/or a conventional CNC router. They are often constrained by the mechanical limits of their cutting table and the performance limits of their existing router.

The VSR frequently replaces the conventional router, while the customer keeps a conveyor-belt cutting system for roll materials. The VSR is therefore positioned as a high-end, high-performance router for semi-rigid materials, while also providing solutions for flexible materials (work overflow, cutting-table downtime, multi-tool operations, etc.).

base (Roland, Mimaki, Epson, HP…) =

strong potential for a VSR proposal.

More and more industrial and craft businesses are adopting the VERSO VSR machine. Beyond its outstanding capabilities in milling, tapping, and tangential knife cutting, a wide range of advanced features set the VSR apart from competing machines.

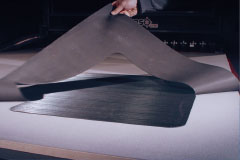

Here are a few examples of what our customers produce:

- Templates for luxury leather goods

- High-end ski bases and cores

- Soundproof cabins made from acoustic felt / aluminium / wood / PMMA

- Cut and engraved electrical enclosures and instrument panels

- Vehicle interior fittings / trim for people with reduced mobility

- Custom-made toilet seats

- Printed foldable bins (grooved Hylite® on both sides, camera alignment)

- Custom packaging (cardboard, foam, polystyrene)

- The French Army also uses the VERSO VSR for various applications.

With its features and capabilities, the VSR is a strong asset for many factories and workshops

Part of the VS series launched in 2020, the VSR is a highly reliable, field-proven machine. Close collaboration with our French distributors has kept us close to customers and their real-world requirements.

Since 2020, all VERSO machines manufactured and sold have been part of the VS family (VS, VS+ and VSR). This platform approach has enabled continuous improvements over time. For example, multiple sensors and safeguards have been added to prevent unexpected errors, including those that can occur with inexperienced or distracted operators.

In the event of a minor issue, our machines can operate in several fallback modes, avoiding production stops whenever possible. This enables the distributor to schedule a service visit within a comfortable timeframe when needed.

In France, our distributors initially limited installations to areas close to their premises (as they often do for large-format printers and plotters). As the reliability of our VS ranges proved itself, they expanded their territory. Today, machines are installed more than 1,000 km away within mainland France, and some are sold internationally.

rigorous machine quality control

Unlike many manufacturers, VERSO develops the CAD/CAM software, firmware and motherboard in-house. This means we can provide a truly end-to-end solution and a single point of contact when support is needed. From the customer’s Illustrator file to the finished part, we cover the entire workflow.

The VSR has been designed to simplify diagnostics. In most cases, the software immediately indicates the most likely cause(s) of a malfunction. When connected to the internet, the VSR sends diagnostic files to our servers, enabling remote assistance and - when necessary - detailed event analysis. The VSR can also receive remote updates.

The installation of the VSR has been made as simple as possible and requires only a short amount of time. Once the gantry and the tools are installed, the machine is ready to be used.

The combination of distributor margin, fast installation, and a limited number of warranty interventions makes the business highly profitable. After the warranty period, maintenance contracts can be offered and are highly valued by customers. Consumables (blades, cutters, milling mats) also represent additional revenue opportunities. If preferred, customers can be directed to partner suppliers so the distributor does not need to manage consumable inventory.

Our distribution policy is designed to avoid competition between distributors. This is why VERSO machines can be sold easily at the current public price.

For many sign-making companies, purchasing a VSR is a significant investment. Demonstrations on a dedicated showroom machine are a key step to reassure prospects and accelerate decision-making.

With a showroom machine, our current distributors can:

- Run customer demonstrations

- Exhibit at national trade shows

- Let customers use the machine while waiting for delivery of their own

- Provide user training

- Train new technicians

- Produce promotional items and sample parts

The showroom machine is available under attractive financial terms and can be renewed annually. In some cases, it also allows us to quickly equip a prospect who has taken on a new contract or whose existing machine has broken down.

It is essential that technicians become confident users of the machines, so they can train operators correctly. This is the most critical point: unsuitable tools or unsuitable working conditions can lead to defects that may be wrongly attributed to a machine malfunction.

Technical training focuses primarily on learning how to identify the root cause of any issue quickly. Simple procedures allow anomalies to be detected and resolved efficiently.